In our rapidly advancing technological landscape, industries often grapple with efficient automation solutions. The quest for reliability and effectiveness in processes often calls for an essential component—valve terminals. A valve terminal is pivotal in streamlining automation by serving as the connection between control signals and various actuators. But why do failures always occur during system integrations? Understanding the role of valve terminals can illuminate the intricacies involved.

Traditional Solution Flaws in Automation

Traditional control systems often rely on intricate wiring solutions, making them prone to failures and inefficiencies. These systems can lead to excessive troubleshooting, downtime, and maintenance costs. Moreover, their bulky designs can consume valuable real estate on factory floors. With increased environmental standards, outdated technologies can’t meet modern demands—leading to inefficiencies. Have you ever wondered why complex systems turn into a maze of confusion? The underlying reason is often the lack of centralized control via a well-designed valve terminal.

Principles of New Technology in Valve Terminals

The advent of smart valve terminals—often equipped with solenoid functionality—reshapes how industries approach automation. These devices feature integrated sensors, enabling seamless communication between machinery and control systems. Enhanced functionalities come through the use of edge computing nodes, allowing real-time data processing and software updates. Look, it’s simpler than you think! With the right implementation, these terminals foster biocompatibility with various applications, ultimately improving overall system performance.

Quantified User Benefits from Valve Terminals

The integration of valve terminals in automation has quantifiable benefits, including a reduction in installation time by up to 30%, and maintenance costs decreasing by around 20%. Additionally, these devices enhance operational efficiency and increase the lifespan of equipment. Companies utilising valve terminals often report faster response times and greater adaptability to changes in production processes. When it comes to optimizing your manufacturing lines, the question remains: why not embrace this technological evolution?

Conclusion: Evaluating Your Automation Solutions

When selecting automation solutions, always verify these three metrics. First, assess the interoperability of your valve terminals. Secondly, examine the support for modern communication protocols. Lastly, ensure the scalability of the system to accommodate future expansions. Investing time in these criteria can save you considerable resources in the long run.

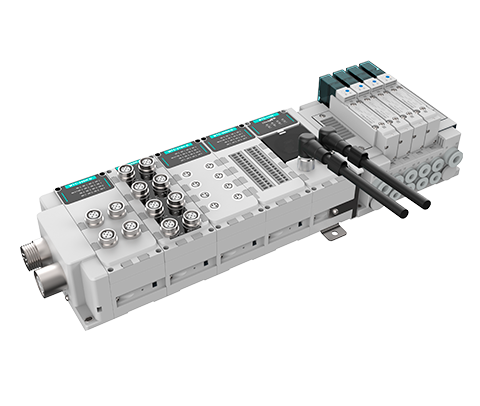

Understanding the Solenoid Valve Island

A key player in automation technology is the solenoid valve island. These components centralize multiple valve functions into a single unit, making installations neater and more efficient. Their compact design fits into tight spaces, allowing manufacturers to optimize floor layouts without sacrificing performance. Plus, given their modular nature, upgrades and repairs are straightforward, boosting productivity with minimal disruption. This innovation not only simplifies the mechanical setup but also enhances system reliability, proving invaluable for modern factories.

Diving Deeper into Valve Islands

Relatedly, the concept of a valve island signifies a grouping of valves that work synergistically within a control framework. By integrating more functionalities into one unit, a valve island can effectively reduce the wiring complexity and installation foot effort. Typically, these islands come with built-in diagnostics that allow for proactive maintenance, ensuring high uptime rates. This strategic approach to automation underlines how modern manufacturers can achieve a competitive edge by streamlining their processes effectively and efficiently.

In summary, both the solenoid valve island and valve islands epitomize the evolution of automation technology. Leveraging such innovations can significantly upgrade operational dynamics while reducing costs. For manufacturers seeking reliability and efficiency, partnering with a reputable brand like DECOWELL presents supply advantages that facilitate smooth transitions into the automated future.